What is Fiber optic cable?

Fiber optic cables are the most advanced network cables, it serves as the backbone for many networking systems including network systems, campuses, office buildings, Fiber optics is steadily replacing copper wires. It is a better and faster means of transmitting communication signals. Today, fiber optics cables can send and receive data across continents without any major data loss.

It consists of very thin strands of glass or special plastics thinner of a human hair in which the data is transmitted as pulses of light.

How fiber optic cable works?

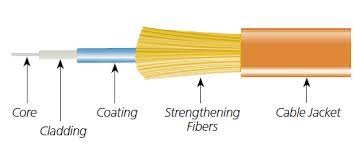

The working principle of fiber optics is based on the “total internal reflection”, this phenomenon happen when the light strikes the interface at an angle greater than the critical angle, then the speed of the light increases and reach the other end. This will permit the light to travel long distance at the speed of light, thus performing a better bandwidth with little alteration.

However, total internal reflection happens in the core between the high refractive index glass and the low refractive index air. The cladding, which is the second layer after the core, can replace air by keeping the light wave contained in the core. It is responsible for reflecting back the light signal to the core, coating is a cushioning material, such as acrylate, it protects the sensitive fiber and preserves the core from scratches and mechanical damage.

How many types of fiber optic cable are on the market?

Optical cable can be classified into various different standards according to their end use, their mode a connectors types. There are two major Optical fibers types, which are single mode fiber cable (SMF) and multi-mode fiber cable (MMF).

Broadly, there are three types of fiber optic cable commonly used: single-mode, multimode, and plastic optical fiber (POF).

What are the preliminary steps for fiber optic assembly?

Cable assembly process depends on the type of fiber optic and its connector type.

We are going to cover the cable preparation for a 900 micron buffered fibers. There are also known as simplex cables generally used in backplane applications, and desktop connection.

Simplex cables are composed of the outer jacket usually 3mm diameters. Kevlar, which are also known as strength members and the 900-micron buffer over the primary buffer coating.

- First, preparing the workspace is a very crucial step, it is better to work on a black surface because it helps to see clearly the fiber.

- Open the connector package and slip the cable support the bushing and the crimp sleeve into the outer jacket of the fiber optic.

- Strip the outer jacket and the Kevlar, using a fiber stripper. It is important to know what your strip length is going to be and the manufacturer of the connector usually indicates that. What you will be left with is a specific length of buffer and some of the Kevlar to cover the whole post of the connector.

- Then remove the protective cladding that surround the field fiber, a heating system can be used to soften the coatings so they can be easily removed.

- Cleaning the bare fiber is a crucial step to remove any coating residue, using the alcohol pad or lint-free cloth dampened with isopropyl alcohol. Once cleaned, the fiber must be prevented from any contact with any potentially contaminated surfaces or materials; this is because even a tiny speck of dust can completely block the light, which can result in bad fusion splices and inadequate bonds.

- Cleaving is the process of cutting the fiber end flat using a fiber optic cleaver. Cleaving is “a professional cute technique” of the fiber core, as the latter is made of glass a “nonprofessional cute” will broke it, leaving scratches of the surface in order to prevent this, using a special cleaving will cut the glass in a smooth manner. With a properly well-done cleaving, the end of the fiber will have a perfectly smooth right angle.

- Inspection: Inspecting BOTH sides of the fiber connection is the ONLY WAY to ensure that it will be free of contamination and defects. Inspecting and cleaning connectors, test ports and reference cords before testing network connectors prevents cross-contamination.

- Fiber Optics Testing: Troubleshooting, Verification, and Certification (Fluke tester). Certification of a fiber optic cabling per IEEE, TIA/EIA, or ISO/IEC standards is necessary to ensure that the link will run the intended application.