Injection molding technology has been in development for almost 150 years. It is a manufacturing solution for the mass-production that consists of melting the plastic materials at a certain elevated temperature, which becomes pliable and ready to be injected under pressure into a mold where the liquid plastic cools and solidifies to form the corresponding product.

There are also various forms of injection molding such as gas-assisted molding, water-assisted molding, microinjection molding, injection foam molding, low-pressure molding, injection compression molding, etc.

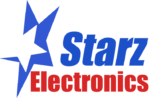

The low-pressure injection molding process has become increasingly used in various industrial applications. It started gradually replacing the traditional high-pressure injection-molding machine in same field. In this blog, you are going to understand why low-pressure molding has become more effective than high-pressure injection molding in electrical and electronic manufacturing.

1. Application:

The temperature in the low injection molding is low (180-240°C) compared to the high application (230-300°C). The low injection machine’s low temperature allows sealing fragile electronic and electric components without damaging its components. Some of the fragile electronic components that require the use of low-pressure injection are; LED lighting, switch and sensor electronics, mobile batteries, camera modules, solar inverters, and some types of cable assembly used in a tough environment like water pomp and aerospace cables.

High-pressure injection molding is widely used for the mass production of plastic processed products that we frequently use in our daily life such as; plastic chairs, plastic bottles, and kitchen appliances. It also can mold electric components that withstand the high temperature that this process applies.

2. Used Raw Materials:

The choice of raw materials used in low injection is limited comparing with the high-pressure injection machine. The latter can use a wide variety of plastic materials including Acrylic or Polymethyl Methacrylate (PMMA), Polycarbonate (PC), Polyethylene (PE), Polypropylene (PP), Polyethylene Terephthalate (PETE or PET), Polyvinyl Chloride (PVC)

3. Protection and Durability:

The low-pressure plastic injection provides higher adhesion and waterproof sealing performance of the electronic compound. However, the traditional high-pressure injection machine does not ensure this strong level of rubber adhesion.

Regarding environmental protection, the high-pressure injection machine is driven by hydraulic pressure, which is unfriendly to the environment. The Low injection machine operates by air pressure therefore, it does not generate pollution to the environment.

4. Process time:

Comparing the time consuming of these two technologies, the low-pressure method takes over again; it can seal the electronics components and have them ready in seconds compared to high-pressure injection molding which could take a much longer process time.

Low vs high-pressure injection molding

| The Low-pressure injection molding | The high-pressure injection molding |

|---|---|

| Injection temperature is low (180-240°C); | Injection temperature is high (230-300°C); |

| The choice of raw materials used in low injection is limited mainly thermoplastic polyamide is used in this process. | A wide variety of plastic materials can be used.. |

| Good Adhesion and high waterproof sealing performance | Cannot glue precision electronic components |

| The glue injection machine is driven by air pressure and has no pollution to the environment. | The glue injection machine is driven by hydraulic pressure, which is not harmful to the environmental. |

At Starz Electronics, we provide low pressure as well as high-pressure molds for a range of connectivity solutions. With an equipped workshop for all necessary equipment and machines, we can make a wide range of mold types for various applications, notably the electronic assembly.

Reference

Fu.H, Xu.H, Ying.L, Yang. Z, Kormakov. S, Wu.D, Sun. J (20 May 2020) “Overview of Injection Molding Technology for Processing Polymers and Their Composites”

https://www.espublisher.com/journals/articlehtml/es-materials-manufacturing/Overview-of-Injection-Molding-Technology-for-Processing-Polymers-and-Their-Composites Engineered Science Publisher LLC